Boeing finishes 787 repairs, closing Everett 'shadow factory'

Published in Business News

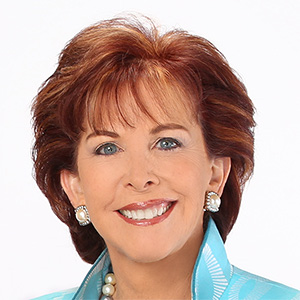

In a significant milestone toward Boeing’s recovery, mechanics in Everett, Washington, last week completed rework on the last of the 787 Dreamliner jets that had to be stored long-term until small gaps at the fuselage joins were repaired, Boeing Commercial Airplanes CEO Stephanie Pope announced.

This marked the end of a long, expensive slog to fix 122 Dreamliners that has locked up the time of hundreds of mechanics, taking them away from regular jet-production work.

The paper-thin gaps were determined not to be a risk to the structural integrity of the airplanes but nevertheless did not meet the manufacturing specification and kept the aircraft from being delivered to airline customers.

The financially draining rework, requiring meticulous disassembly then reassembly of the aircraft, has spanned five years.

Other teams of mechanics are still reworking 737 Maxes in storage, of which about 55 remained at the end of January.

Boeing has referred to the 787 and Max rework projects as “shadow factories,” because they take workers away from the main assembly plants. Chief Financial Officer Brian West said in January he expected to close out both this year, immediately improving profit margins.

Writing on LinkedIn on Friday, Pope said the mechanics who completed the 787 work will now move onto new assignments, “with many of them helping us advance the 777/777X program.”

“This is what we mean when we said we would shut down the ‘shadow factories’ and turn our full attention to building all-new airplanes,” Pope said.

Though the completion of the fuselage-gap rework is a positive milestone, other slowdowns in the jet-production system remain.

A separate inventory of unfinished 787s newly built in North Charleston, S.C., has been piling up due to parts shortages.

The main holdups are new, still-uncertified business class seats and a part called a heat exchanger in the jet’s environmental-control system, supplies of which were interrupted by the war in Ukraine.

At an industrial conference in February, Boeing CEO Kelly Ortberg cited “good progress” on getting an alternative supply of heat exchangers but said “seats continue to be a problem.”

And the Everett mechanics freed up by the end of the 787 rework may soon have to help rework the inventory of about 30 previously built 777Xs that are lining unused runways at Paine Field, the first of them parked there for the past six years.

Those were built in advance of the 777X completing its flight tests, which extended much longer than expected and continue today.

Only when the giant new plane is certified can all those jets be taken out of mothballs, relubricated and updated with system changes.

A $6.3 billion hit

But at least the main 787 issue is behind Boeing now.

After initial discovery of the 787 fuselage-gap problem in summer 2020 — in the middle of the COVID-19 shutdown — deliveries of the 787 were halted starting that fall, resumed briefly the following spring and then halted again in May 2021 until August 2022.

Between November 2020 and August 2022, just 14 Dreamliners were delivered. Boeing in 2023 estimated that this 787 debacle racked up about $6.3 billion in “abnormal costs.”

By the end of last year, just 25 Dreamliners requiring the fuselage-gap rework remained.

Rolled out last week, the last one was a 787-10, the largest Dreamliner model, a jet built in South Carolina in December 2020.

Before the fuselage gaps on this jet were reworked, Boeing in 2023 used it for long-distance test flights from Seattle to Tokyo, Singapore and Bangkok. It was painted in the livery of Boeing’s ecoDemonstrator Explorer program, investigating how to reduce fuel usage and carbon emissions by optimizing flight paths.

It will now be repainted for delivery to an airline. According to aircraft data sites, it will go to TAAG Angola Airlines.

However, even with the fuselage gaps fixed, deliveries of these repaired aircraft will be slow.

In many cases, they will now be taken by a different airline than the originally intended customer and so need to be repainted or have new interiors installed — which could again come up against the parts shortages.

On Friday, Pope wrote on LinkedIn that Boeing will work with airlines to deliver the remaining reworked airplanes “over the course of this year and next.”

©2025 The Seattle Times. Visit seattletimes.com. Distributed by Tribune Content Agency, LLC.

Comments